The Challenge: Overcoming Inconsistent Quality from Overseas Suppliers

Updated 3/05/2024

An Australian manufacturer of aluminium skirting boards faced a growing problem: the quality of their imported plastic components was inconsistent and unreliable.

This negatively impacted their production schedule, product quality, and customer satisfaction. They sought a local supplier who could deliver consistent, high-quality components at a competitive price.

The Solution: Ramjet Plastics' Local Expertise and Value Engineering

Ramjet Plastics was engaged to design and manufacture an injection moulding tool to replace the client's unreliable overseas supplier. Our focus was on delivering a superior quality component at a competitive price, all while ensuring a reliable local supply chain.

How Ramjet Plastics Helped:

Understanding Client Needs: We worked closely with the client to understand their specific requirements,quality concerns, and cost constraints.

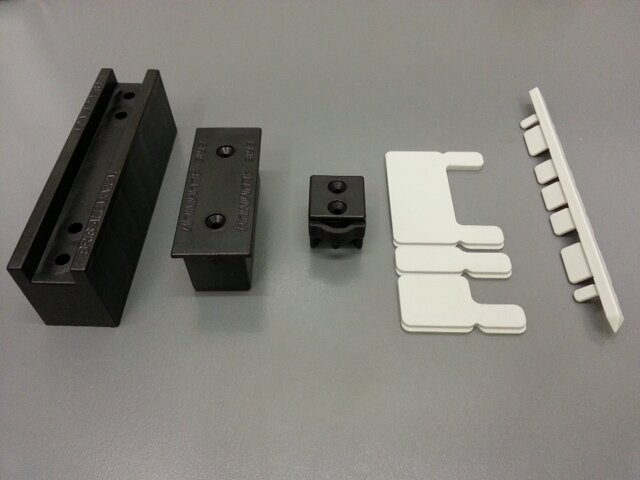

Innovative Design: Our engineers designed a new component that consolidated multiple parts into one,simplifying the client's inventory and streamlining their production process.

Local Manufacturing: By producing the components locally, we eliminated supply chain delays and ensured consistent quality control.

On-Time Delivery: We met the client's tight deadline for a large-scale project on the Gold Coast, proving our reliability as a local partner.

Value Delivered: Enhanced Quality, Flexibility, and Local Supply

Ramjet Plastics delivered tangible benefits to the client:

Improved Quality: The new injection moulded components were of superior quality and consistency compared to the imported parts.

Increased Flexibility: The client could order smaller, more frequent batches, reducing inventory costs and improving cash flow.

Local Support: With a local supplier, the client had access to immediate support and faster turnaround times for any issues or modifications.

Expanded Product Range: Ramjet Plastics has since helped the client expand their product range with additional locally manufactured components.

Are you looking for a reliable, high-quality injection moulding partner in Australia? Contact Ramjet Plastics today for a free consultation and experience the difference local expertise can make.