Brisbane's Premier Plastic Injection Moulding Tooling Design & Manufacturing

Ramjet Tooling, established in 2004 as an extension of Ramjet Plastics, is your one-stop shop for comprehensive, cost-effective plastic injection moulding solutions. We understand the desire for a seamless experience, from initial concept to final product delivery.

Your Experienced Injection Moulding Tooling Partner in Brisbane

With over 25 years of industry expertise, Ramjet Tooling has the knowledge, skills, and state-of-the-art equipment to transform your ideas into reality. We've refined our processes through years of experience, ensuring a simple, efficient, and cost-effective journey for our valued clients.

Complete Tooling Design & Manufacturing Services

Our modern, well-equipped facility, conveniently located in Brisbane's south-west corridor, is your ideal partner for design and development. We offer a full range of services, including:

Concept drawings: Bringing your initial ideas to life.

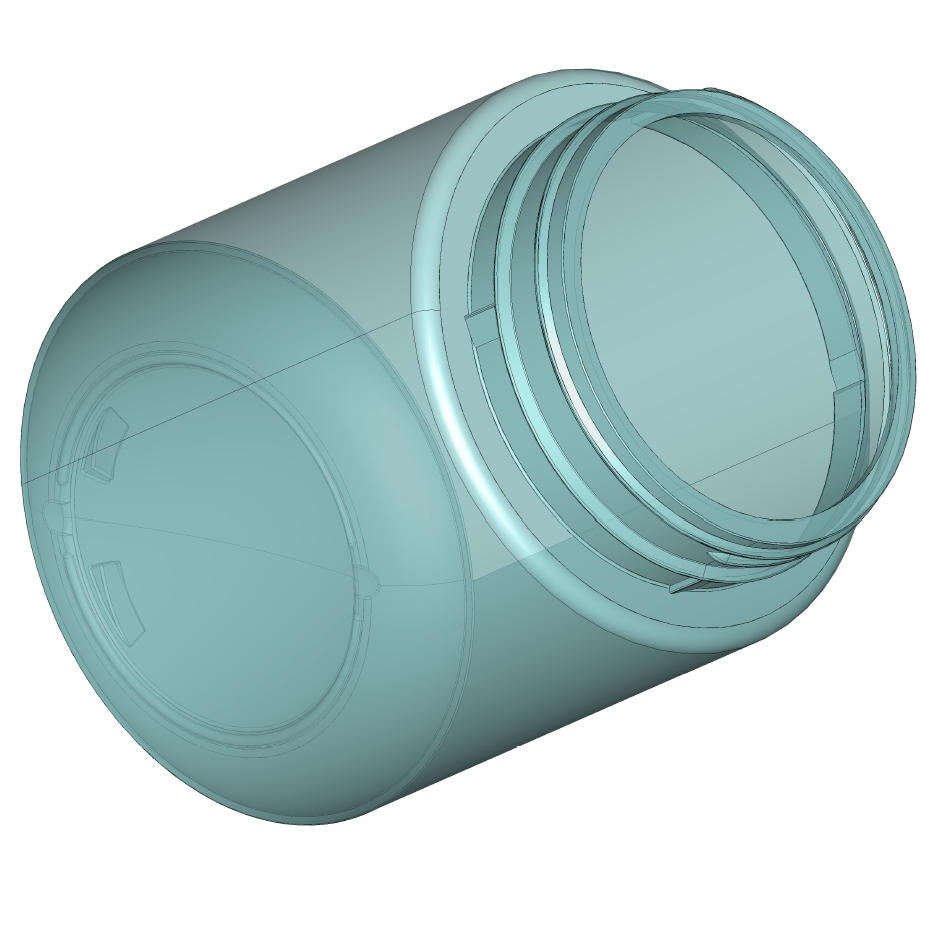

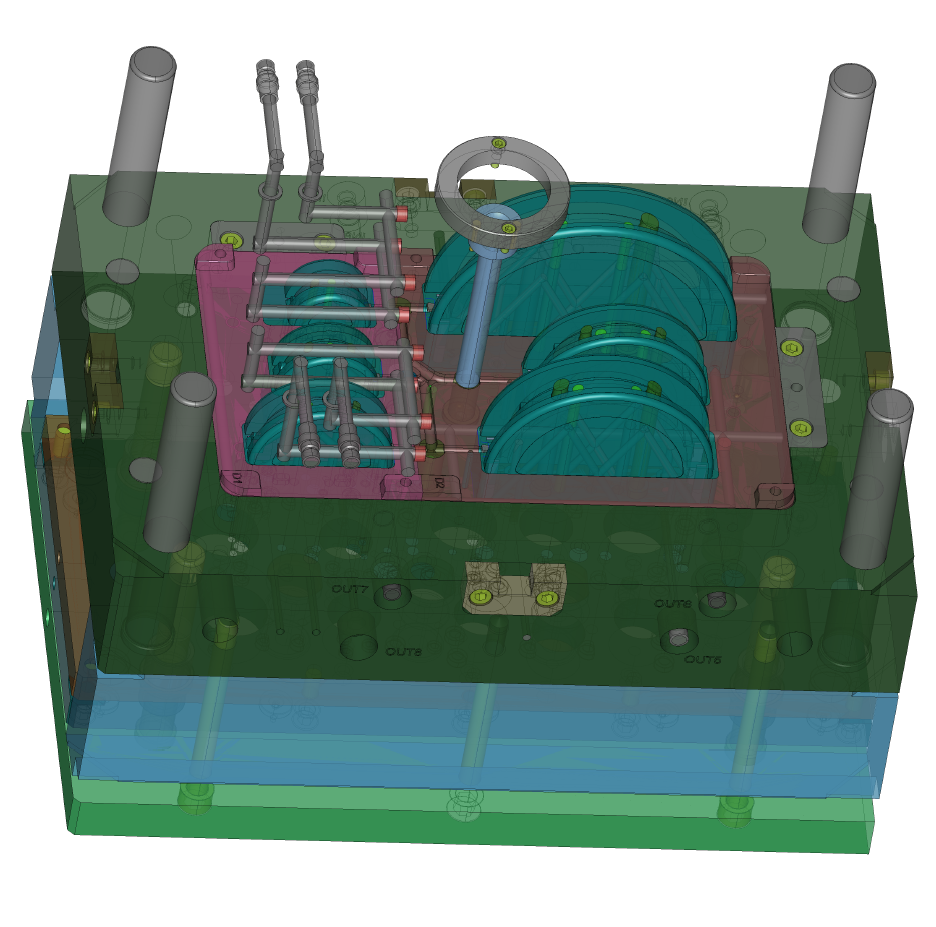

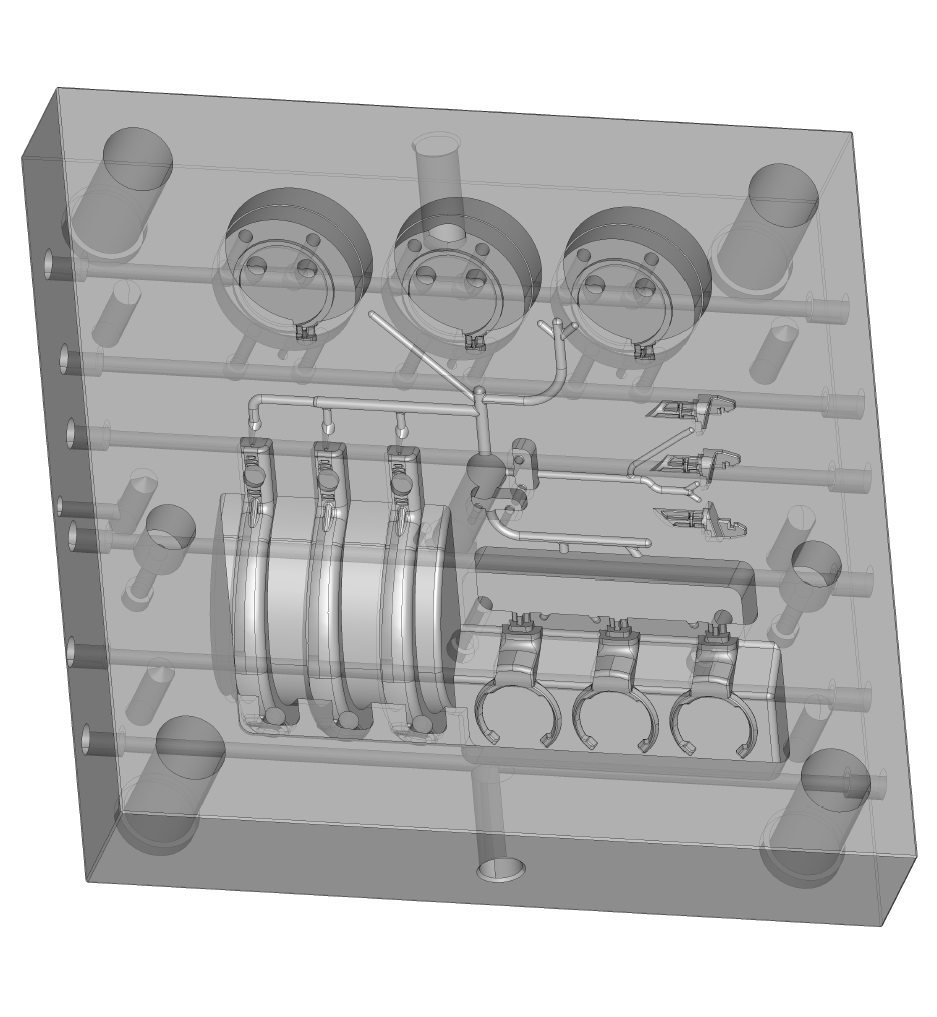

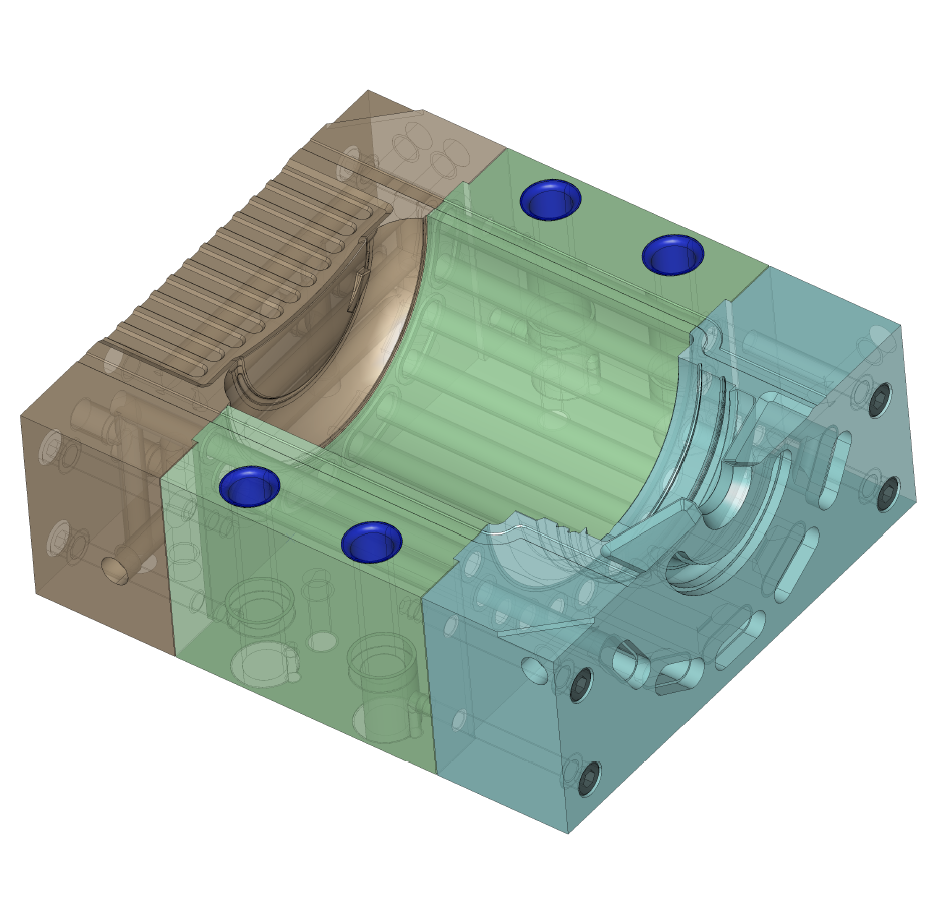

Computer-aided design (CAD): Creating precise, detailed 3D models of your components.

Design prototyping options: Testing and refining your designs before production.

Our team expertly optimizes your component design for maximum manufacturing efficiency without sacrificing functionality. We then use our custoCAD CAM software package to translate your 3D design into precise instructions for our CNC machining centres, EDM (electronic discharge machines), and manual machinery. Our highly skilled toolmakers then create top-quality moulds that precisely match your design..

Commitment to Excellence

We live by world-class best practices and a results-driven culture. Our commitment to quality means that Ramjet Tooling consistently delivers exceptional results for our clients.