When an Australian manufacturer was suddenly left without a supplier for their crucial plastic component, they faced a daunting challenge. Determined to source locally, they discovered Ramjet Plastics – a leading injection moulding specialist right here in Brisbane.

A leading Australian manufacturer of rotomoulding powders and water tank components faced a challenge: a key component in their range was becoming too expensive to produce due to labour-intensive secondary processes.

This high cost was impacting sales and hindering their competitiveness in the market.

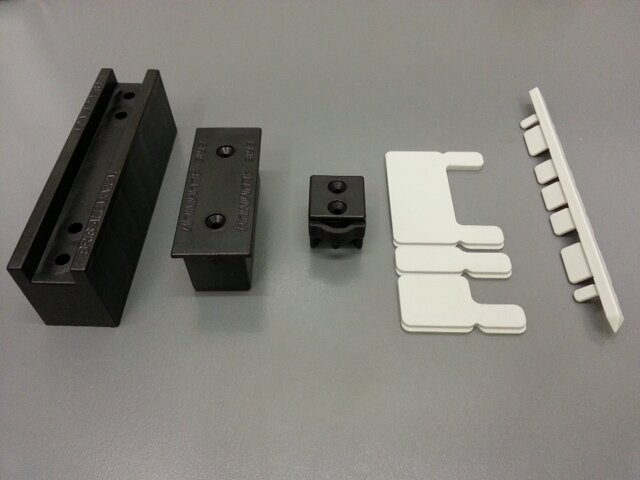

An Australian manufacturer of aluminium skirting boards faced a growing problem: the quality of their imported plastic components was inconsistent and unreliable. This negatively impacted their production schedule, product quality, and customer satisfaction. They sought a local supplier who could deliver consistent, high-quality components at a competitive price.

A major Australian manufacturer of access systems for commercial, industrial, and residential buildings faced a critical challenge. Their plywood flooring and walkway components were becoming a safety hazard due to inconsistent quality,and the logistical complexities of working with wood were impacting efficiency.